While one of the central ideas of the Internet of Things is to bring together information from various devices, this can be done perfectly only when the right information is provided at the right time. This can be done by leveraging Augmented Reality which can be used to visualize relevant and actionable data over your environment on an as-needed basis through the means of a headset or mobile device. With Augmented Reality, users get a completely immersive experience of data in relation to their environment. For example, if you are a maintenance engineer, looking at heavy machinery will tell you exactly where the problem areas might exist and which components would need replacement. Or if you are a farmer, it would be able to provide you with information on the moisture content in soil and fuel in your tractor or any expected diagnostic issues in your tractor before you turn it on. Many large organizations such as Microsoft, NASA, Volvo, Autodesk, and Caterpillar have made huge investments in the field of AR. Microsoft’s Hololens has seen various use cases being tested by Autodesk and NASA. The augmented reality (AR) market was valued at $10.5 billion in 2022, which was roughly $3.5 billion in 2017. This number is estimated to reach a whopping $198 billion in 2025. To expand on this, we will cover ten real world problems that could be solved by AR and IoT.

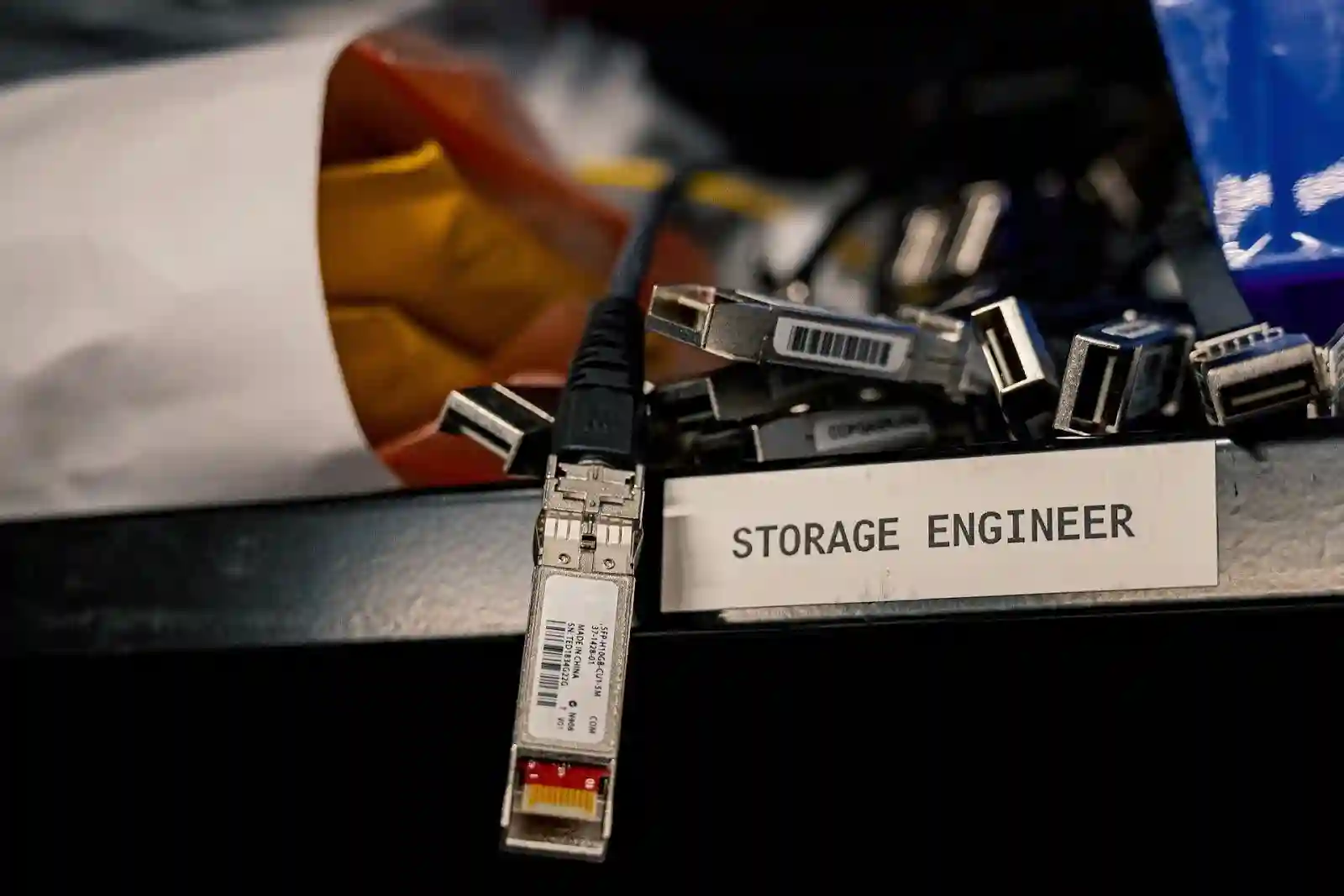

1. Cutting Inefficiency and Diagnosing Technical Problems

Augmented Reality can help you see important and pertinent sensor data and KPIs along with any operational warning or production failure while walking down a production line. Even though this information is normally visible on a desktop application, contextually viewing this data when it matters the most ensures that users make the right decisions with increased efficiency. This would involve connecting as many sensors as can be connected together, extracting data from them, and depending on the context, displaying what is most user-friendly, efficient and relevant. Additionally, such systems can also allow users to interact with them. For example, user can view the 3D replica of the machine, get enterprise system information such as who owns the item, when it was last serviced, etc. The user would also be able to view sensor data around RPMs, temperature, and oil.

2. AR Helmets

Companies like DAQRI are developing helmets that don’t only protect workers on the industrial floor but also enable them to spot hazards and provide live assistance when repairing equipment. Such smart helmets can provide step by step instructions to perform some form of assembly or provide them with thermal vision to spot components that are overheating. The technology can ensure that users reduce time spent referring to printed instructions or booklet.

3. Visualizing Product Design

It is often difficult for development and engineering teams to understand or visualize the design created by designers. AR can give designers the ability to visualize designs as if they are present in the room, provide feedback, make changes to their CAD/CAM diagrams and visualize the changes immediately using headset. Such designs can also be overlaid over existing products by the engineering team to visualize the extent of changes required. This would allow product designers and engineers to interactively discuss product refinements. This can also allow architects, designers and engineers to visualize upcoming buildings around them, see how their designs might look. Urban planners can also visualize the whole city plan or layouts using AR visualization headset.

4. Detecting and preventing machine failures

Any machine failure and steps to fix the problems can be determined through the use of IoT and AI. For example, this can be elucidated through the example of centrifugal pump. Real time sensors will monitor machine conditions and detect anomalies and real time CFD analysis triggered to pinpoint the cause. Using AR, a real time image or CAD diagram can be projected on top of the pump to show exact steps for fixing the machine.

5. Monitoring crops and farm vehicles

In case of droughts, sensors planted strategically in soil can provide farmer insights on whether soil has enough moisture and if not, alert the farmer regarding dry patches. The farmer can also keep tabs on the temperature of the soil. Additionally, farmers can sync the sensors present in tractors and pumps with their mobile application to receive alerts when they are running out of fuel or if temperature is too high.

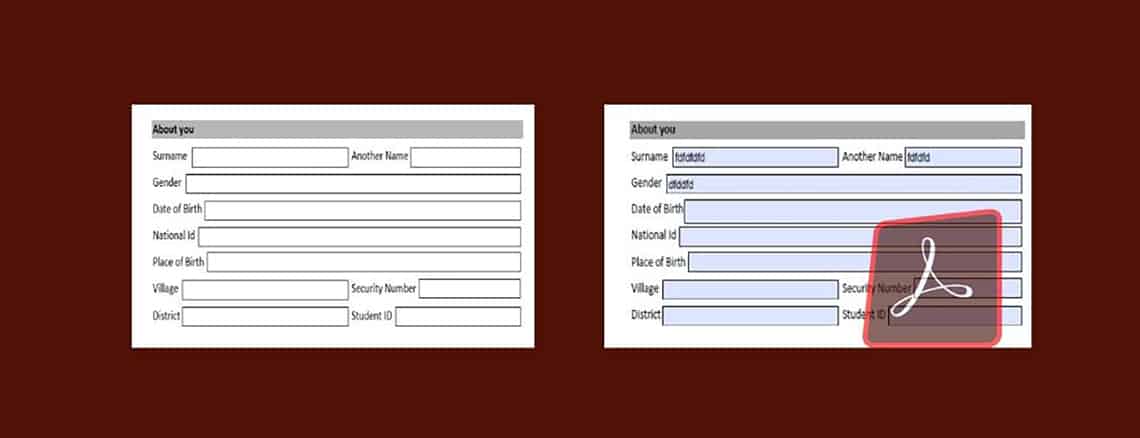

6. Assembly assistance through the use of technical documents

“A picture is worth a thousand words”. This saying is true especially in case of assembly process. User manuals and technical documents can overcomplicate sometimes simple processes which might include regular repetitive process of assembly of industrial equipment. Augmented Reality can help by overlaying the assembly instructions or diagrams on top of the assembly steps. It can be used to overlay text, circuit diagrams, videos and augmented 3-D animations over pieces of equipments. They can also be used to show videos of previous actual assembly steps captured either by the person assembling it or by another worker.

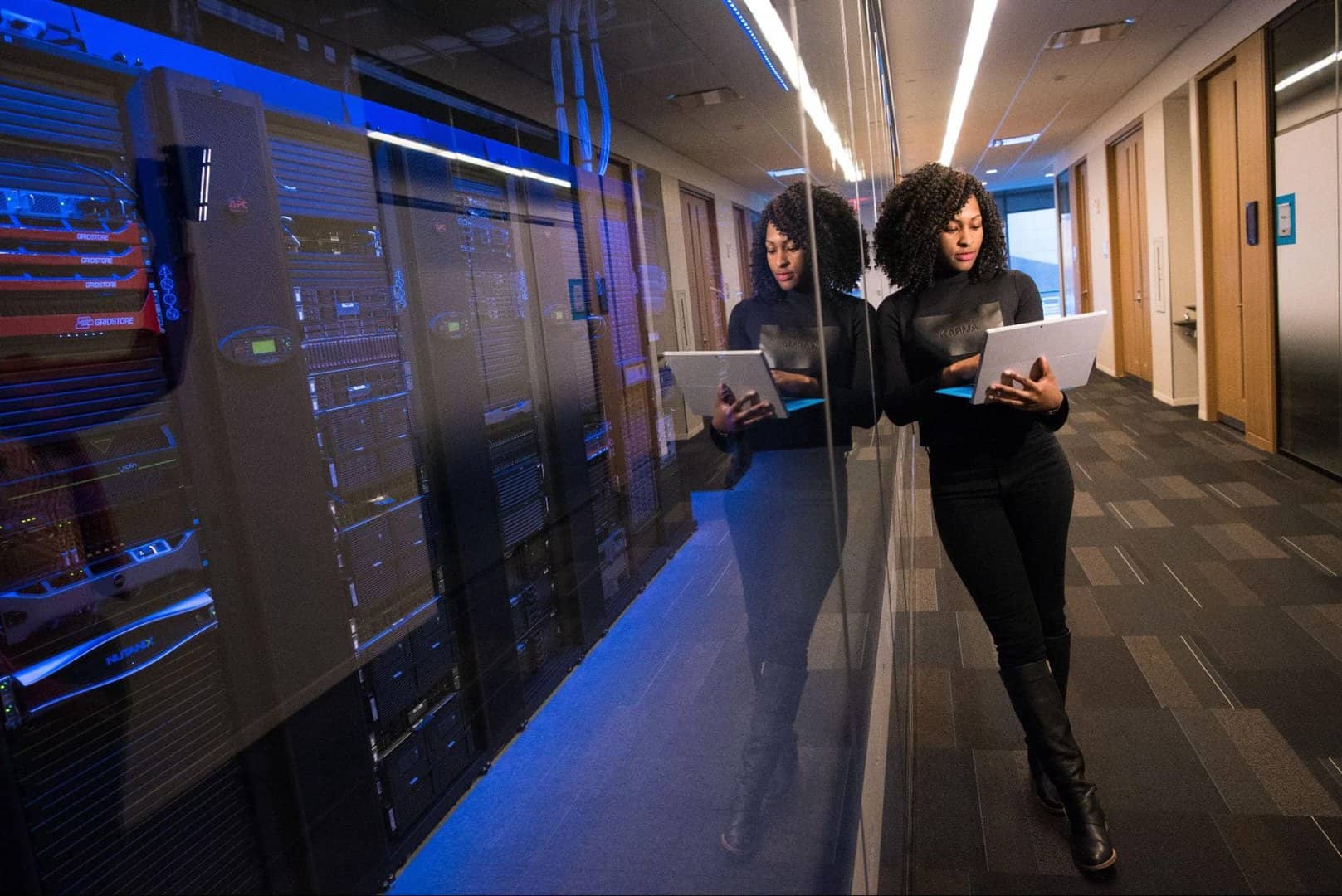

7. Real time/Field Assistance

AR can be used to provide real time assistance when field engineers visit site to repair an equipment. Specialists are quite expensive and hence can be harnessed every time a product goes rogue onsite. Field engineers, on the other hand, need to make multiple visits to the customer’s location to fix the same problem increasing the overall cost of fix.AR and AR headsets can allow field engineers to garner the help of specialists on an as needed basis while on the field. The specialists can view the issues through the headset, provide user instructions and in case of lack of understanding, show exact steps of assembly using CAD diagrams through the headset.

8. Reducing cost of shipping freight

Currently, shipping of heavy equipments is an expensive process since this is manually performed and is not route optimized. AR can increase safety, reduce cost and pollution associated with the shipping process by allowing companies to control drone ships from remote control centers. This would allow a set of professionals adept at using AR technologies to monitor the drone ships that otherwise solely rely in AI and machine learning for getting directions.

9. Business Logistics

AR presents a lot of opportunity to increase efficiency while reducing cost across business logistics including transportation, warehousing and route optimization. For example, logistic companies can utilize AR headsets to display the shortest route within a warehouse to locate an item and pick it for shipping. Headsets can also be used to display the order in which items need to be picked so that they can be shipped quickly and efficiently.

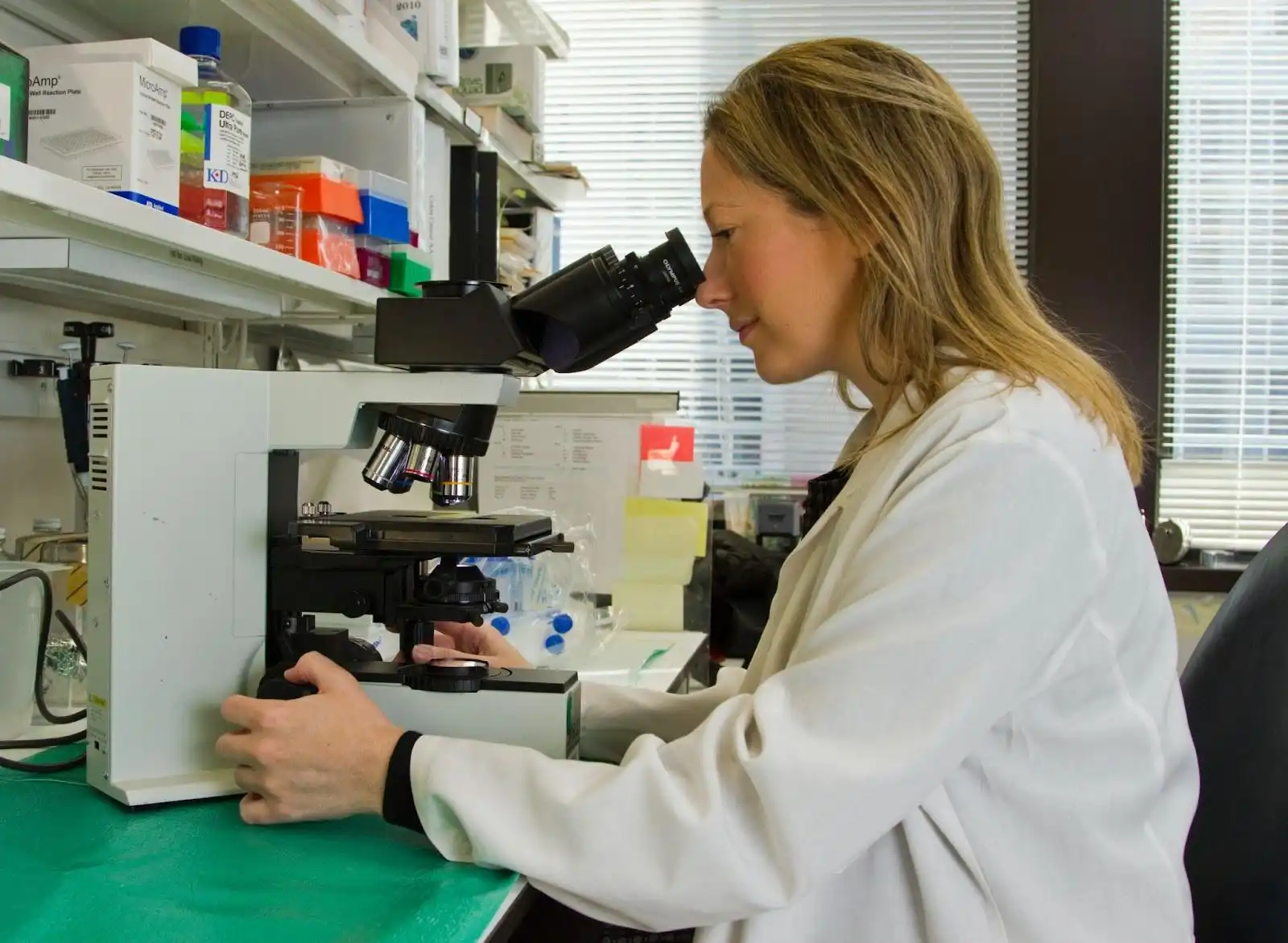

10. Medical Training

AR can allow technicians to operate MRI equipment and perform complex surgeries. Students can even learn anatomy, practice surgeries,and delve deeper into human body using 3-D projections using AR headsets Though the implementations of AR are many, lab technicians can also perform basic service of instruments themselves. For example, consider that there is a clog in a machine following which the lab technician would be unable to run any cleaning cycles. Normally, he would have to call up a service technician for help. However, AR will allow the lab technician to view the instrument through headset and provide instructions to clean the aperture.So, closing the loop, we believe IoT and AR are at a place where they can transform the world around them especially in cases where they work in cohort. The time is right to identify the most impactful use case in your business and leverage these technologies to maximize revenue and efficiency or minimize cost.

.png)

.png)

.webp)